This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

High performance of absorbency

Comfort and Safety in Operating Romm

Water repellency

Barrier to pathogenic microorganism

Breathability

Liquid detention

Elettric charges dispersion

Drapability

Operating room: microfiber gown

MICROFIBER

- Fabric with null linting

- Resistant to fluid and bacteria penetration

- Antistatic carbon fiber

- Light and breathable

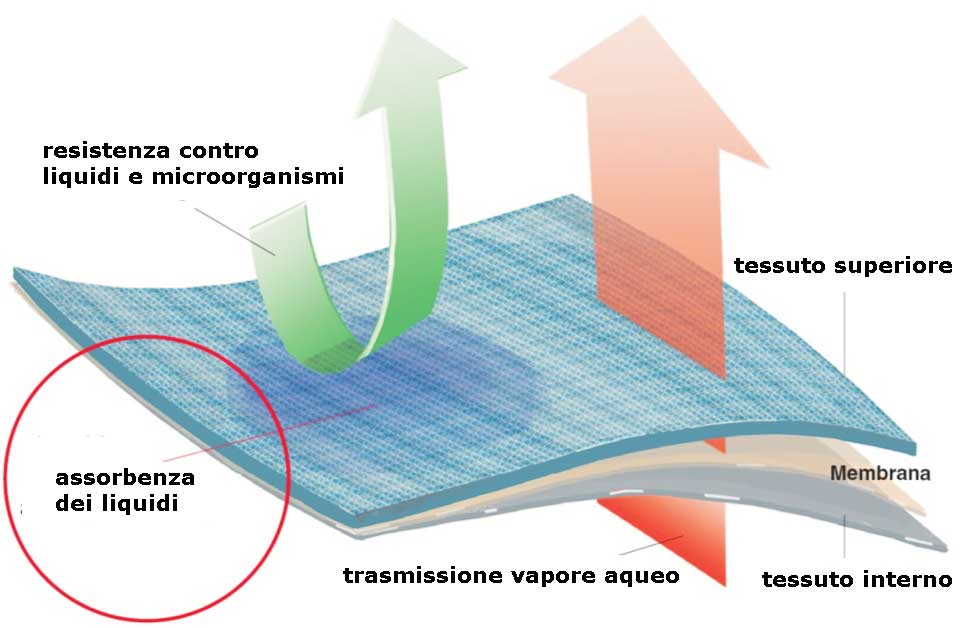

Operating room:trilaminate gown

TRILAMINATE FABRICS

C.F.B. ‘ s high performance trilaminate fabrics improve the requirements improsed by the regular EN 13795, and widely respond to the EU regulation 2017/745,offering the following benefits:

- 100% of impermeability to bacteria,virus and type of liquid

- tensile strenght,tear strenght and busting strenght higher than the requirements of EN 13795

- volatile fibers optimization,water absorbency for effective control of liquids

- further benefits such as high permeability to water stream and excellent adherence to operating surfaces

Maximum operating comfort

If all surgical operations performed in a year in Italy would be carried out with preparation of surgical room with RFT, it would have the following benefits, in terms of social and environmental sustainability.

300.000 kg

of wates less

220.000 kg

of CO from disposal less

6.000

jobs more (1 job every 650 surgical operations)

300.000 kg

of unused raw material thanks to the fabric recycling

NUMBERS

The use of Reusable Technicala Fabric in operating room presents sure environmental benefits that, in association with the quality, safety and protection characteristics, make the product highly performant.

Under the social and economical profile, the cost of the product life, thuesne, o tfh Ree usable Technical Fabric produces annually important savings in different fa ctors.

Percentage reduction:

INDIRECT MANAGEMENT COSTS REDUCTION:

administrative, personal, stocking and device handling, etc…

Furthermore, the sterilization companies mediate the relationship between producers of operating roomtextile devices and final users, ensuring one stable point of reference, quality standards and

significative economies of scale.

NATIONAL COSTS REDUCTION:

in the RTF production chain, 80% of the value added are focused on the national territory, with important implications in the regional level, due to the localization of implant in all regions. It follows that Italy, beyond earning a good part of the value added in terms of gross domestic product, saves the devices costs of handling and disposal.

COLLECTING AND ENVIROMENTAL COSTS REDUCTION:

the characteristic of reusing the RTF products reduces the general quantity of waste (-300.000 kg); furthermore, at the time of disposal, products in RTF are industrial wastes assimilable to urban wastes, since the disposal happens after the quality check placed downstream of the disinfection process.

Maximum operating comfort

The barrier effect is always the result of a compromise between impermeability and comfort, and it’s achieved in different levels, to satisfy different degrees of protection in relation to the biologic risk in the operating room.

Total protection fabrics

The front part of the gown and the sleeves are fully made in hughly protective barrier fabric.

The belt

the adjustable belt is provided with special heel to allow the operator a comforming regulation in absence of contamination.

Fit

the barrier gown indicates characteristic of great fit, thanks to the raglan sleeves, and great pratically for the easiness of closing and opening. It is very protective since it is very wraparound.